Welcome To The Armstrong`s Website.

A few pictures and information on Thornley Colliery and the viliage where I worked (1954) and lived (1947) for some time until about 1968.

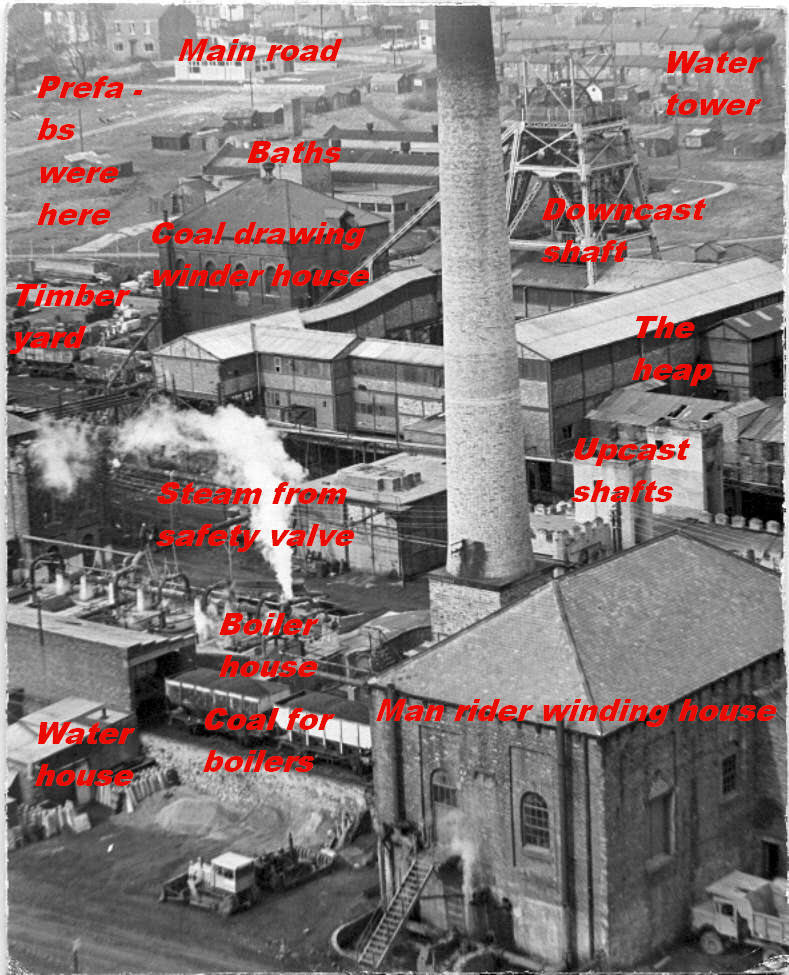

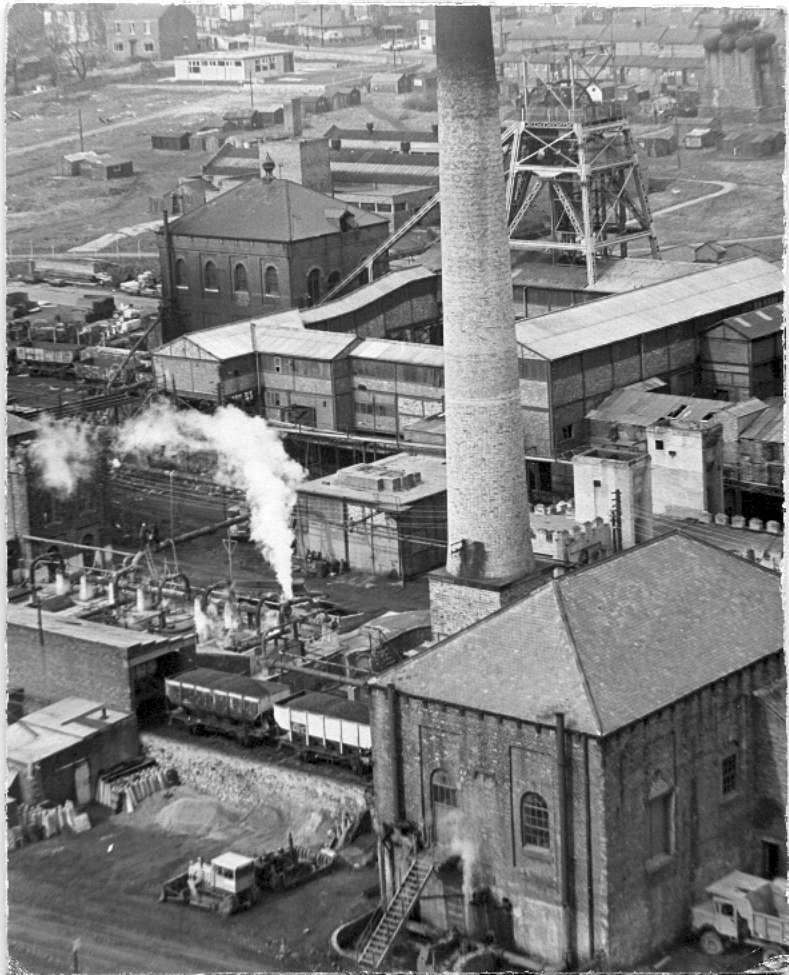

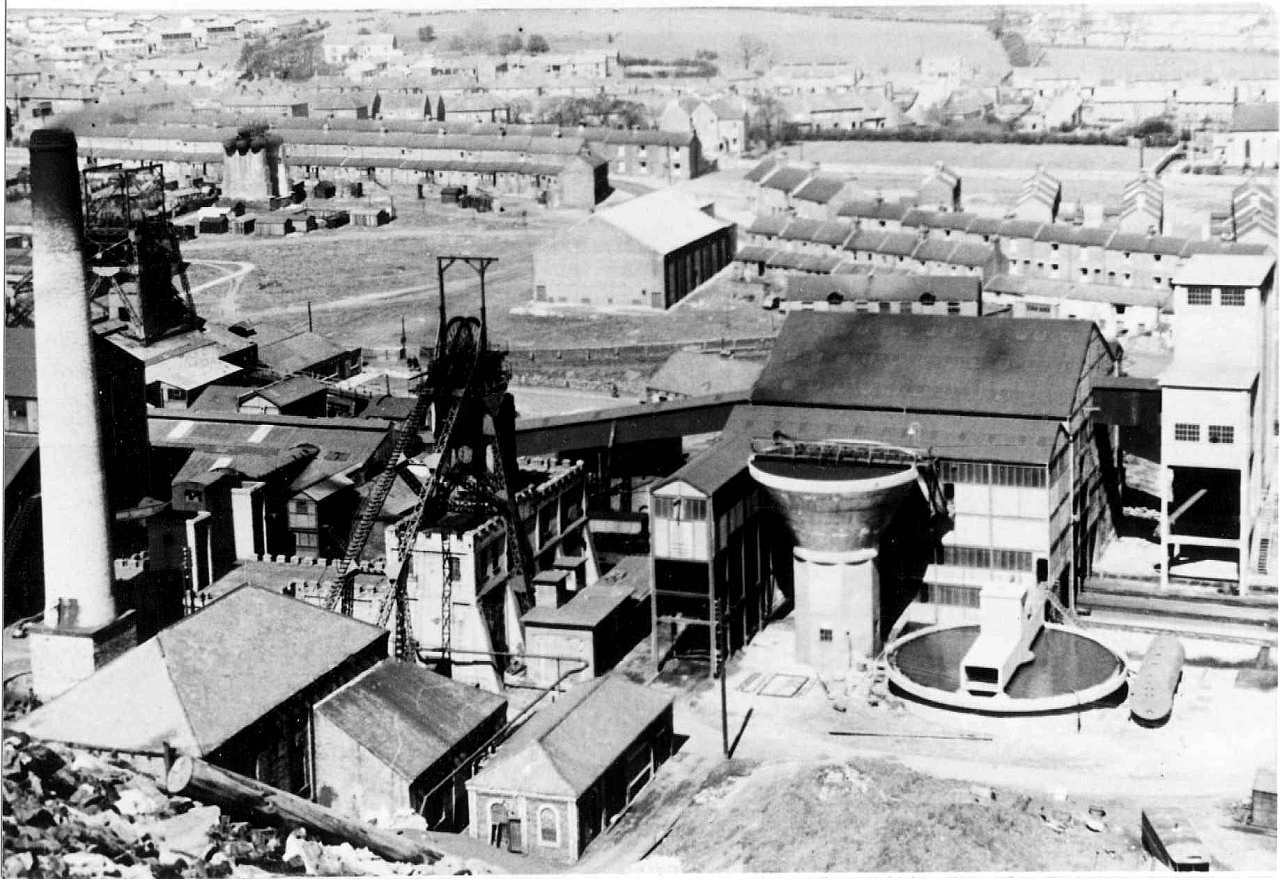

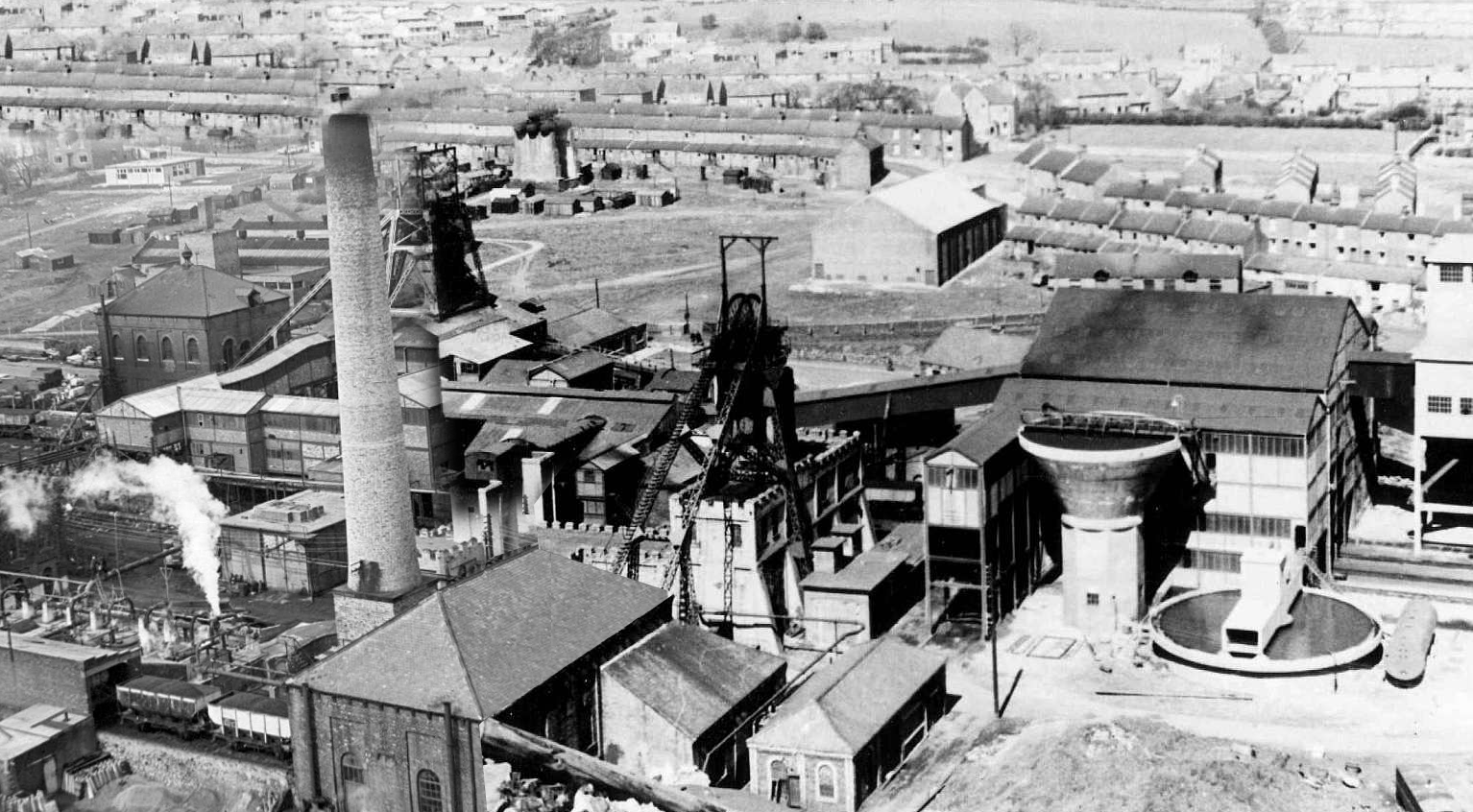

Below is a kind of panoramic view from the top of the heap.The workshops, stores and old timekeepers office , were to the right about 200yds, just not in shot. There were, welding shops,( Billy Thompson and Jackie Barker) electric shops (Mattie Convery) painting and joinery shops,(Horace, Tot Bullock, Davy Swallow) tub shops,(Stan Dower, Dick Gutteridge,Gowan Straughn, Tom Armstrong) blacksmiths shops,(Jimmy Abs, Arthur Bosamworth, Freddy Spence, Tommy Nicholson) boiler shops,(Jimmy Mc.Gregor, Billy Jones) fitting shops,(Herby Lambert, Davy Scott) and plumbing shops.Gordon Abs and Rocky Hutchinson) To name but a few of the interesting characters.

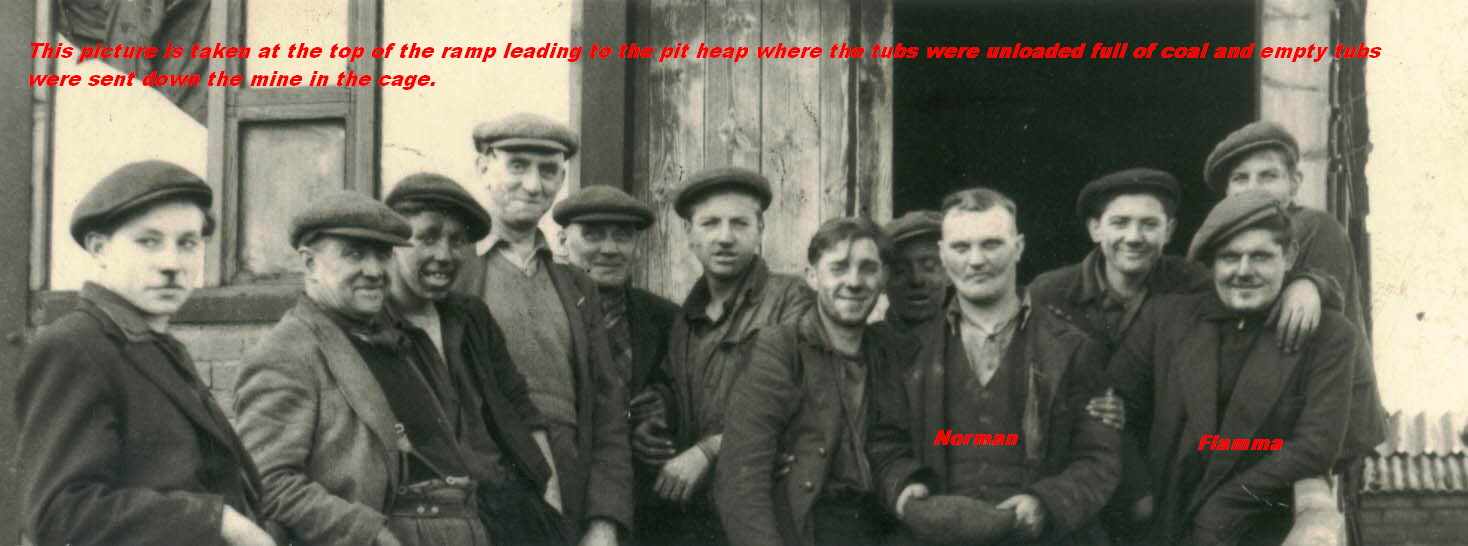

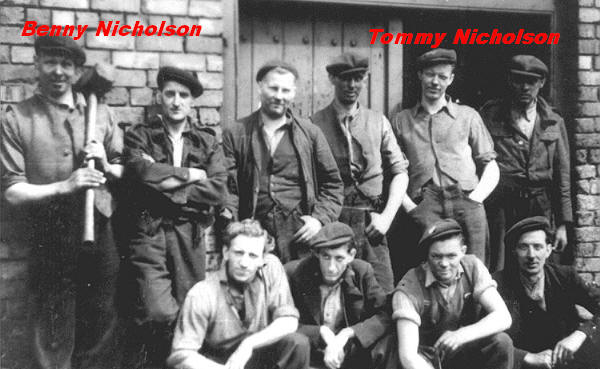

Below are some of the characters that worked at Thornley colliery when I was there in the 50`s and 60`s.

The above picture was taken outside of what we called the welfare, bottom of Thornley, now called a comunity centre, it had a snooker room with 6 tables in it on the right hand side and a dance hall on the left hand side with a refectory. Dances were held there every Saturday night.

Billy Thompson worked as a fabrication welder in the welding shop with Jacky Barker. Alf Bushby and Jimmy Abs worked together with another Blacksmith called Arthur Bosomworth. Jimmy was allegedly the best Blacksmith at the Yard. Apparently when they took him on he was left handed and was told to work right handed as the were not going to turn the anvil round for him. Consequently has was as good with the hammer in his left hand as his right. Alf was on light work employed as a labourer I think. Jimmy was the cage smith and Arthur was an engine plane worker.

I knew the two lads named personally, don`t know the others, sorry I do not know the full names only the names they used at the pit. I note that Norman and the chap with his arm around him, have removed their caps for the picture to be taken. This is typical of Norman, a very sweet man. He worked in the blacksmiths shop with me for a long time as a striker and he was very good at it too. Swinging a hammer all day at the hot metal. Deserved a lot more respect than he was given at the time. Flamma was a real funny character, worked on the heap (pit head) loading and unloading coal and stone tubs. The twin deck cage came up with 4 small tubs on each deck and was unloaded. Later larger steel tubs were used and they were twice the weight. Took some moving. There were steel plates just in front of the shaft, that were kept wet with a rag on a wire from a barrel full of water, to make turning the tubs easier. The tubs were sent to the appropriate place depending on what they contained. The on setter would shout out the instructions for every tub........ COOOAAALLL or STOOOANE would ring out and the tubs were manhandled to be tipped onto the screens below or sent to the large heap, blantyre, if they were stone. The empty tubs were returned to the back side of the shaft to be sent back down the pit and re filled. Flamma and his mates had to make sure that they got the tokens (round brass numbered disks on string), off the tubs and credit the miners with the appropriate loads that they were due to.

Above left with Billy Middleton`s guitar is, Joe Butler, also Joe in the middle and on the right Billy Middleton. Both were apprentice blacksmiths at Thornley Colliery about 1957 onwards.

I started work a couple of years earlier then them and we worked together for some time until I left the blacksmiths department to take up a job teaching at Sunderland. The above two pictures on the right were taken at a mechanics annual night out, at a Hartlepool Masonic Hall, Marquis of Granby Lodge, I think it was called, about 1958. The picture of Joe with guitar may have been taken in Billy Middleton`s back garden or even Mrs Hopes garden at Thornley as Joe stayed with her for some time.

Thornley Colliery about 1954 to 1965.

I remember my first day at the Colliery. I had been to see the Manager Mr Welch three times, up in his office, asking him for a job in the workshops. He finally said I could start Monday so I reported to the training officer, Henry Hubbard.

On the first day Henry took me and a couple of other would be apprentice boys around the pit yard showing us various place, starting with the lamp cabin and then dropped us of at the very large workshop complex. I wanted to be an electrician, but was deemed not clever enough so I had to be a blacksmith. (as happens, best move I ever made, never regretted it.) You would have to pay a fortune for the kind of education I was in for.) I was sent to work with Billy Straughan to start my apprenticeship, with the proviso that if a place came up in the electricians shop I could apply for it. It never did.

The Lamp Cabin. Men going down the pit would enter the door,(just behind the car park sign), pick up there Safety Lamp and battery lamp and then go straight up an open air ramp, behind the Lamp Cabin to the man rider shaft. Note the chains around the car park. Billy Straughn and I made those chains and fitted them to the cast concrete posts made by the building section. They were cast with a 3/4" bolt in the top with a heart shaped link to hold the ends of the chains. If we got the chains a bit long we just put an extra twist in them to shorten them. About 1957.

The workshops at Thornley Coliery.

The workshops at Thornley in 1955 were housed in seven very large buildings. Each building must have been about 100yds long by 20yds wide. The first building was an electricians shop with the Paint shop on the back of it. Then there was the joiners shop next to that. Both of the forgoing shops were shorter than the following metal shops Then there was the first blacksmiths shop, called the tub shop, next was the main blacksmiths shop followed by the loco / boiler shop and then the fitting shop. All of the metal shops, after the joiners shop were joined by internal, large doorways about 10ft square, so one could access all areas with ease. The plumbing shop where Gordon Abs and “Rocky Hutchinson” worked with Billy Parker, was joined on to the fitting shop at right angles and was about a quarter the size of the other shops. The welding shop where Jackie Barker, Billy Thompson and Roy Jones worked was separate, across the yard from the electricians shop.

The Tub Shop.

The tub shop had rails running into it so that the damaged tubs could be run in for repair. There were two blacksmiths hearths in there.One was worked by Gowan Straughn and Stan Dower. The other By Dick Gutteridge. I worked in there with Stan and Gowan on several occasions and ended up in there with welding and cutting equipment after I have served my appreniticeship.

The Main Blacksmiths Shop.

The main shop had Two fires on the left, Freddie Spence ran one and Billy Staughn ran the other. There were four fires on the right. Billy Hoban, Arthur Bosomworth, George Ashford and Jimmy Abs were in charge of them respectively.

This is where I served most of my time as an apprenice. Working with all of the men. Later on we and an intake of blacksmiths from other pits nad several men came from Windgate, Bob Farnsworth, Tommy Hewartson and from Wheatley Hill. Tommy Nicholeson and his brother Benny.

The Boiler or Loco Shop.

This was the largest of the shops and could hold 4 trains at a time. Standard gauge rails ran into it through very large doors so that steam engines could be driven in for boiler repairs etc. Jimmy McGregor was in charge with Billy Jones to help him. I worked in there with Jimmy and Billy on several occasions.

This is a picture of one of the last trains that Bill Jones and I used to shunt about the yard (unofficially of course) That is the old weigh cabin behind it where all of the coal leaving the pit was weighed. There was a gate out onto the housing estate just to the left for people to cross the line.

I lived for some tome this side of the gate in the pit yard, in a two house street called office villas. No 1 and no 2. I lived in both of the houses. I had a few friends that lived just the other side of that gate, in what would now be classed as slums. David Scott, Howard Hind and Ragga Jones.

Howard was a good school friend, I remember he had a lot of sisters and brothers, nick named Bosh, due to his unconventional,(at the time), German soldier cropped hair style. Howard was born at Station Town, (same as myself) County Durham, and lived at Thornley when I knew him. He left school at 15 to work at Thornley Colliery, County Durham, until its closure when he moved to Welbeck and began work at Warsop Main colliery, from where he retired in 1989 when the pit closed, thank you Margaret. Left this world in 27/07/2006. Far too young.

The Fitting Shop.

I would be in there just about every day, getting holes drilled or using one of the fine gringing wheels. The shop had a large lathe, very large drilling machine, run by Arthur Boner and a plainer, but mainly consisted of benches, vices and tool box cupboards.

Training for the mine works at Washington.

So, I started at the pit, apprentice blacksmith. First I had to do what they called training. I was packed off the Washington training centre for 13 weeks. Staying overnight through the week and returning home on Fridays. Nightmare...... sleeping in a dorm, boarding school style. Down pit all day and nothing to do all night until bed time. I hated it. However it all makes you what you are in the end. I did meet up with the first friend I ever had when I was about 4 years old at Station Town. A lad called Colin Thwaits. He was also doing his mining training. I guess he started at Wingate colliery the same time I started at Thornley.

Working at he pit.

I remember the first Job I had to do. I had to carry two lengths of 6” x 4” steel angle 10ft long from the blacksmiths shop to the pit heap so that they could be sent down the mine. The chap in charge of me Billy Straghn and I had to balance the angle on our shoulders and walk about half a mile with it. Now this was nothing to Bill who had been a blacksmith for 20 odd years, but I thought I was about to die. The angle iron must have been about half a ton and it dug into my shoulders. It was so heavy I could not breath. We eventually got it to it`s destination and I managed to drop it off my shoulder on to the ground, with a 1....2...3... frm Bill. I am sure Billy did not realize how hard it was for a schoolboy and he probably had most of the weight in any case. Boy it was hard, but it was nothing really, harder stuff was to follow. Several of the men in the blacksmiths had already said to me

“ tak notice o me n al mak a man o the Tommy”.

I am sure you can work that one out for yourself. Well I suppose they did eventually do just that.

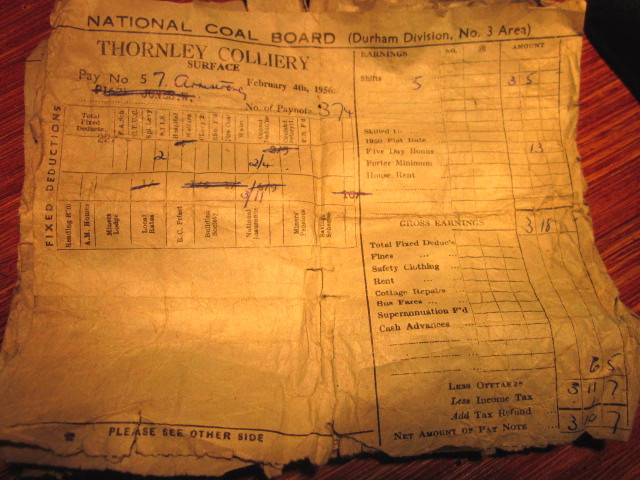

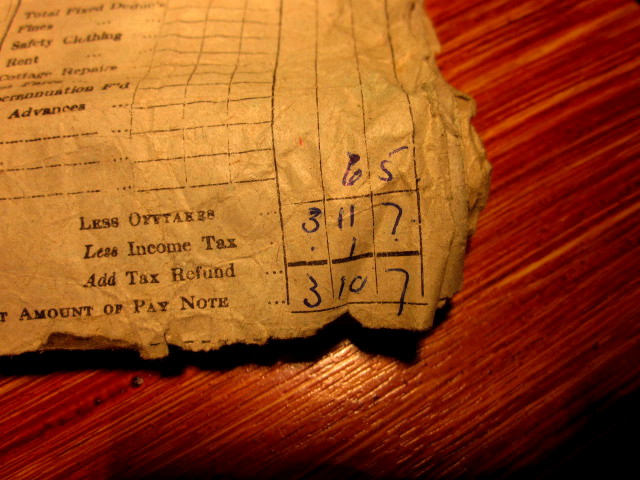

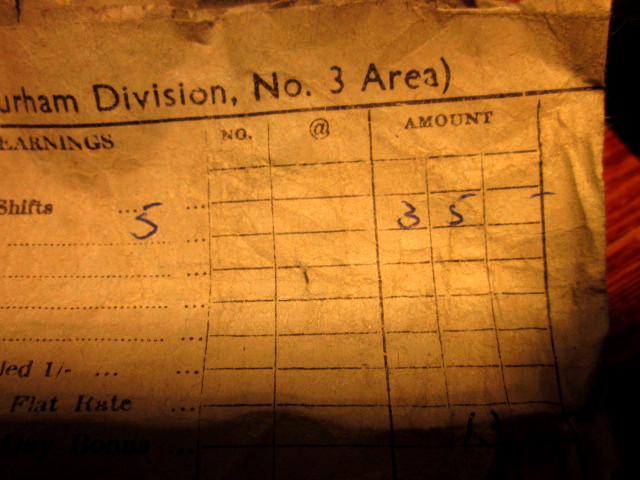

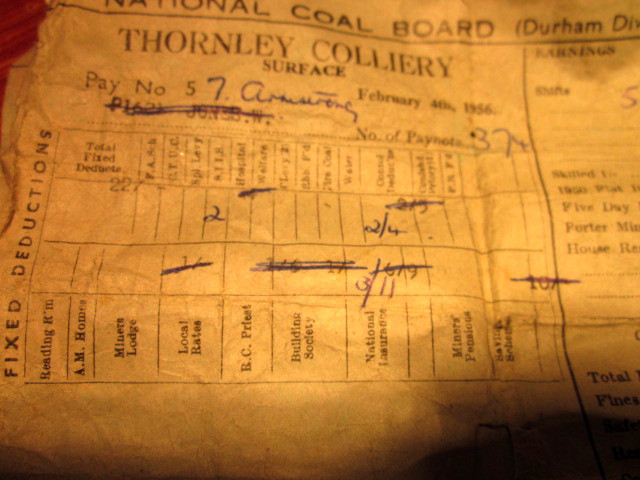

Below an old pay note from me first starting work.

As you can see I worked all week, five 8 hour shifts for £3.10s and 7p. I took the money home to my mother and got £1.00 pocket money. I went straight down to Kirks the fruiters (yes the lady with the twin boys) in Thornley front street and paid 17/6 (almost the whole pound) for a revolver, cowboy gun, with removable shells, that had been in Mrs Kirks window for weeks and I had longed for it, constantly going to the window to look at it. So that left me 2/6p, half a crown, or twelve and a half new pence for the week. So you can see that “when I became a man I put away all childish things”. Anyway that`s what my first weeks wages went on. In fact I had to work a fortnight for it as we worked a running on week before we got paid.

General ("Mehanics of the mine") yes that is what they called us, work.

So we started at 7am in the morning and worked until 4pm in the evening with a break for dinner at 12 noon. The night shift, just two people started at 4 pm and worked until 12 midnight. The over night shift, just two two people again worked from 12 midnight until 7 am the next morning. The day shift Blacksmiths did general maintenance and repairs of all major steel components at the mine. The other shifts were there for coverage of breakdowns and examinations of creepers, hoppers and other night idle machinery.

The night shifts were easy to do but the times were very unsocial, sleep depravation was a problem. The older Blacksmiths did not have to do night shifts and this was quite a bone of contention with some of the men that did.

A Typical Apprentice Blacksmiths day.

Up at 6am and walk to the pit head baths, change form home clothes on the clean side of the baths and pass through the shower units to the dirty side. Put on your pit clothes and make you way to the time office through the lamp cabin, to be clocked in before 7 am. Then the long walk to the Blacksmiths shop with the other mechanics and apprentices, all doing exactly the same. When I arrived at the shop it was my first job to light the forge I was allocated to that day and get it ready for the Blacksmith to use it.

I had no idea how to do this at first of course and was told by one of the men to get some “oily waste” from the fitting shop and light that to start the fire. Oily waste was a kind of wool that the fitters wiped there oily hand and machines on. This is how most things were learned, by doing it.

Very noisy blowers to start and a very very smoke filled barn type place. about 10 forges all going together, combined with someone, like the cage smith (Jimmy Abs) dipping hot chains in to his tar pit, sometimes you could not see 10 yards and had to go outside for a breath of fresh air. Much to the amusement and scorn of the older Blacksmiths.

So I served my time, five years apprenticeship and when I was twenty one, out of my time and seen as a man, they carried me around the shop shoulder high singing he`s a jolly good fellow. I have never forgotten that special moment it meant a lot coming from them and was not normal. Thinking back I recon I had quite a hard time, but as the years went by, I became better at the job than they were, I worked very hard and always wanted to be the best. One way or another intentionally or not they partially moulded me into what I am. They had a great affect on my outlook and I learned a lot about human nature, the best and the worst of it.

Education Provided by the N.C.B

I left school in 1954 / 55 with no education. For some reason I decided to go to night school and went to Welfield at Wingate three nights a week taking what they calld a J1 and J2.

Eventually Bunty Hubbart the training officer at Thornley colliery at the time, got me a place on “day release” IE. I got one day off work every week, with pay to be educated. I attended a college at Durham for a while and then transferred to Sunderland College of Further Education.

Studying S1 S2 S3 and many other courses in welding engineering and metallurgy under a great tutor “Professor Les Wimpeny”. Another great influence on my thinking. Thanks to the N.C.B. and it`s educational policy I eventually replaced Les wimpeny as, first an assistant lecturer, then a full lecturer and then what they called an L2 in charge of the department. But that is another story.

On the subject of getting a day off with pay every week, I used to drive the foreman Blacksmith nuts as I also had a day off every week to go to civil defence training( we were expecting the bomb to be dropped at any time in those days so I was trained in rescue ) and he (the foreman) spent some time looking for me to give me a job when I was not there. So eventually I worked Monday went to college on Tuesday, worked Wednesday, went to civil defence on Thursday, worked Friday and normally did not work overtime on weekends as I was off racing motorbikes. Thanks NCB.

That is some of the Civil Defence team on the left and (Bunty) Henty Hubbart in the right hand picture, far right.

The front row of the defence team are, left to right, Kenny Lonsdale Fred Bradly and Tot Bullock. Tot went with me to pick up my first motorbike from Cowies in Durham, Flamwelgate Moor, in 1958. He was quite a guy and we were friends for some time.

The chaps on the back row of the defence team are left to tight, don`t know, Norman Fort, Matty Convery, don`t know, Les,??? Fred Bradlie`s son and the name of the big fella on the right I can not remember, but he taught me a lot about the work we were traning for. Quite a gentle giant that worked as a bricklayer at the pit.

MORE TO FOLLOW

BACK TO HOME PAGEThe Fitting Shop.

I would be in there just about every day, getting holes drilled or using one of the fine gringing wheels. The shop had a large lathe, very large drilling machine, run by Arthur Boner and a plainer, but mainly consisted of benches, vices and tool box cupboards.

Training for the mine works at Washington.

So, I started at the pit, apprentice blacksmith. First I had to do what they called training. I was packed off the Washington training centre for 13 weeks. Staying overnight through the week and returning home on Fridays. Nightmare...... sleeping in a dorm, boarding school style. Down pit all day and nothing to do all night until bed time. I hated it. However it all makes you what you are in the end. I did meet up with the first friend I ever had when I was about 4 years old at Station Town. A lad called Colin Thwaits. He was also doing his mining training. I guess he started at Wingate colliery the same time I started at Thornley.

Working at he pit.

I remember the first Job I had to do. I had to carry two lengths of 6” x 4” steel angle 10ft long from the blacksmiths shop to the pit heap so that they could be sent down the mine. The chap in charge of me Billy Straghn and I had to balance the angle on our shoulders and walk about half a mile with it. Now this was nothing to Bill who had been a blacksmith for 20 odd years, but I thought I was about to die. The angle iron must have been about half a ton and it dug into my shoulders. It was so heavy I could not breath. We eventually got it to it`s destination and I managed to drop it off my shoulder on to the ground, with a 1....2...3... frm Bill. I am sure Billy did not realize how hard it was for a schoolboy and he probably had most of the weight in any case. Boy it was hard, but it was nothing really, harder stuff was to follow. Several of the men in the blacksmiths had already said to me

“ tak notice o me n al mak a man o the Tommy”.

I am sure you can work that one out for yourself. Well I suppose they did eventually do just that.

Below an old pay note from me first starting work.

As you can see I worked all week, five 8 hour shifts for £3.10s and 7p. I took the money home to my mother and got £1.00 pocket money. I went straight down to Kirks the fruiters (yes the lady with the twin boys) in Thornley front street and paid 17/6 (almost the whole pound) for a revolver, cowboy gun, with removable shells, that had been in Mrs Kirks window for weeks and I had longed for it, constantly going to the window to look at it. So that left me 2/6p, half a crown, or twelve and a half new pence for the week. So you can see that “when I became a man I put away all childish things”. Anyway that`s what my first weeks wages went on. In fact I had to work a fortnight for it as we worked a running on week before we got paid.

General ("Mehanics of the mine") yes that is what they called us, work.

So we started at 7am in the morning and worked until 4pm in the evening with a break for dinner at 12 noon. The night shift, just two people started at 4 pm and worked until 12 midnight. The over night shift, just two two people again worked from 12 midnight until 7 am the next morning. The day shift Blacksmiths did general maintenance and repairs of all major steel components at the mine. The other shifts were there for coverage of breakdowns and examinations of creepers, hoppers and other night idle machinery.

The night shifts were easy to do but the times were very unsocial, sleep depravation was a problem. The older Blacksmiths did not have to do night shifts and this was quite a bone of contention with some of the men that did.

A Typical Apprentice Blacksmiths day.

Up at 6am and walk to the pit head baths, change form home clothes on the clean side of the baths and pass through the shower units to the dirty side. Put on your pit clothes and make you way to the time office through the lamp cabin, to be clocked in before 7 am. Then the long walk to the Blacksmiths shop with the other mechanics and apprentices, all doing exactly the same. When I arrived at the shop it was my first job to light the forge I was allocated to that day and get it ready for the Blacksmith to use it. I had no idea how to do this at first of course and was told by one of the men to get some “oily waste” from the fitting shop and light that to start the fire. Oily waste was a kind of wool that the fitters wiped there oily hand and machines on. This is how most things were learned, by doing it. Very noisy blowers to start and a very very smoke filled barn type place. about 10 forges all going together, combined with someone, like the cage smith (Jimmy Abs) dipping hot chains in to his tar pit, sometimes you could not see 10 yards and had to go outside for a breath of fresh air. Much to the amusement and scorn of the older Blacksmiths. So I served my time, five years apprenticeship and when I was twenty one, out of my time and seen as a man, they carried me around the shop shoulder high singing he`s a jolly good fellow. I have never forgotten that special moment it meant a lot coming from them and was not normal. Thinking back I recon I had quite a hard time, but as the years went by, I became better at the job than they were, I worked very hard and always wanted to be the best. One way or another intentionally or not they partially moulded me into what I am. They had a great affect on my outlook and I learned a lot about human nature, the best and the worst of it.

Education Provided by the N.C.B

I left school in 1954 / 55 with no education. For some reason I decided to go to night school and went to Welfield at Wingate three nights a week taking what they calld a J1 and J2. Eventually Bunty Hubbart the training officer at Thornley colliery at the time, got me a place on “day release” IE. I got one day off work every week, with pay to be educated. I attended a college at Durham for a while and then transferred to Sunderland College of Further Education. Studying S1 S2 S3 and many other courses in welding engineering and metallurgy under a great tutor “Professor Les Wimpeny”. Another great influence on my thinking. Thanks to the N.C.B. and it`s educational policy I eventually replaced Les wimpeny as, first an assistant lecturer, then a full lecturer and then what they called an L2 in charge of the department. But that is another story.

On the subject of getting a day off with pay every week, I used to drive the foreman Blacksmith nuts as I also had a day off every week to go to civil defence training( we were expecting the bomb to be dropped at any time in those days so I was trained in rescue ) and he (the foreman) spent some time looking for me to give me a job when I was not there. So eventually I worked Monday went to college on Tuesday, worked Wednesday, went to civil defence on Thursday, worked Friday and normally did not work overtime on weekends as I was off racing motorbikes. Thanks NCB.

That is some of the Civil Defence team on the left and (Bunty) Henty Hubbart in the right hand picture, far right.

The front row of the defence team are, left to right, Kenny Lonsdale Fred Bradly and Tot Bullock. Tot went with me to pick up my first motorbike from Cowies in Durham, Flamwelgate Moor, in 1958. He was quite a guy and we were friends for some time.

The chaps on the back row of the defence team are left to tight, don`t know, Norman Fort, Matty Convery, don`t know, Les,??? Fred Bradlie`s son and the name of the big fella on the right I can not remember, but he taught me a lot about the work we were traning for. Quite a gentle giant that worked as a bricklayer at the pit.